Based on PC and CAN communication technology, We offer a complete servo hydraulic system solution for the plastic injection moulding machine industry.

Control PC, Servo drive and Servo motor, hydraulic pump and circuit manifold etc, all integrated into one complete system, with standardized mechanical connection and software engineering platform. it make servo hydraulic system (SHS) system easy to be adapted to different kinds of plastic injection moulding machines.

All SHS system are 100% strictly tested before delivered to customer.

Dozens parameter of SHS system are careful tested.

Based on years experience, We developed special SHS software platform for plastic IMM, each movement of IMM is defined with special PID parameter to achieve best performance of plastic injection machine.

Together with best PLC control system and Servo drive system, significant advantages and benefits are achieved.

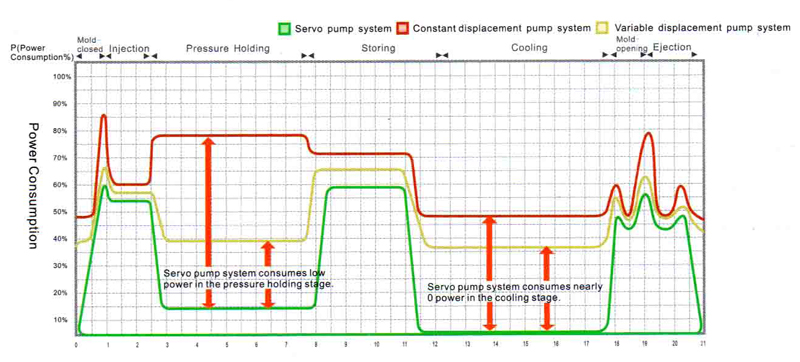

Compared with traditional constant/variable displacement pump systems, the servo pump system combines servo motor's fast stepless speed regulating and hydraulic pump's self pressure adjusting, bringing tremendous energy savings which can reach up to 80%.

Under the control of the excellent PID module, noicy level of IMM greatly improved.

| SPECIFICATION | IV55 | IV70 | IV85 | IV95 | IV120 | IV155 |

| output volume (L/min) | 35 | 45 | 55 | 70 | 86 | 110 |

| rated pressure (Mpa) | 140 | 140 | 140 | 140 | 140 | 140 |

| maximum pressure (Mpa) | 160 | 160 | 160 | 160 | 160 | 160 |

| installed power (Kw) | 6.2 | 7.5 | 8.9 | 8.9 | 13 | 17 |

| drive power (KW) | 7.5 | 7.5 | 11 | 11 | 15 | 18 |

| hole size (inch) | 1/2" | 3/4" | 3/4" | 1" | 1" | 1 1/4" |

| flange size (mm) | 38.1x17.5 | 47.6x22.2 | 47.6x22.2 | 52x26 | 52x26 | 59x30 |

| hole size (inch) | 3/4" | 1" | 1 1/4" | 1 1/2" | 1 1/2" | 2" |

| flange size (mm) | 52.4x26.2 | 58.7x30.2 | 58.7x30.2 | 70x36 | 70x36 | 78x43 |

| pumping unit size (mm) | 581x290x345 | 673x290x345 | 684x290x345 | 697x290x345 | 764x290x345 | 819x290x345 |

| weight total (KG) | 66.2 | 75.5 | 76.5 | 86.4 | 93.1 | 117.2 |

| electric cabinet size (mm) | 540x325x600 | 540x325x600 | 540x325x600 | 540x325x600 | 540x325x600 | 540x325x600 |

| weight total (KG) | 55 | 55 | 55 | 55 | 56 | 56 |

| SPECIFICATION | IV195 | IV245 | IV295 | IV365 | IV445 |

| output volume (L/min) | 140 | 175 | 210 | 250 | 320 |

| rated pressure (Mpa) | 140 | 140 | 140 | 140 | 140 |

| maximum pressure (Mpa) | 160 | 160 | 160 | 160 | 160 |

| installed power (Kw) | 21 | 27 | 41 | 51 | 61 |

| drive power (KW) | 22 | 30 | 37 | 45 | 55 |

| hole size (inch) | 1 1/4" | 1 1/2" | 1 1/2" | 1 1/2" | 1 1/2" |

| flange size (mm) | 59x30 | 70x36 | 70x36 | 70x36 | 79.4x36.5 |

| hole size (inch) | 2" | 2 1/2" | 2 1/2" | 2 1/2" | 3" |

| flange size (mm) | 78x43 | 89x51 | 89x51 | 89x51 | 106.4x62 |

| pumping unit size (mm) | 912x290x345 | 936x290x345 | 1012x370x457 | 1010x370x457 | 1131x370x457 |

| weight total (KG) | 124.2 | 154.8 | 216.3 | 238.4 | 266.4 |

| electric cabinet size (mm) | 540x325x600 | 540x325x600 | 625x338x770 | 625x338x770 | 625x338x770 |

| weight total (KG) | 57.6 | 66.6 | 88 | 129.1 | 133.1 |